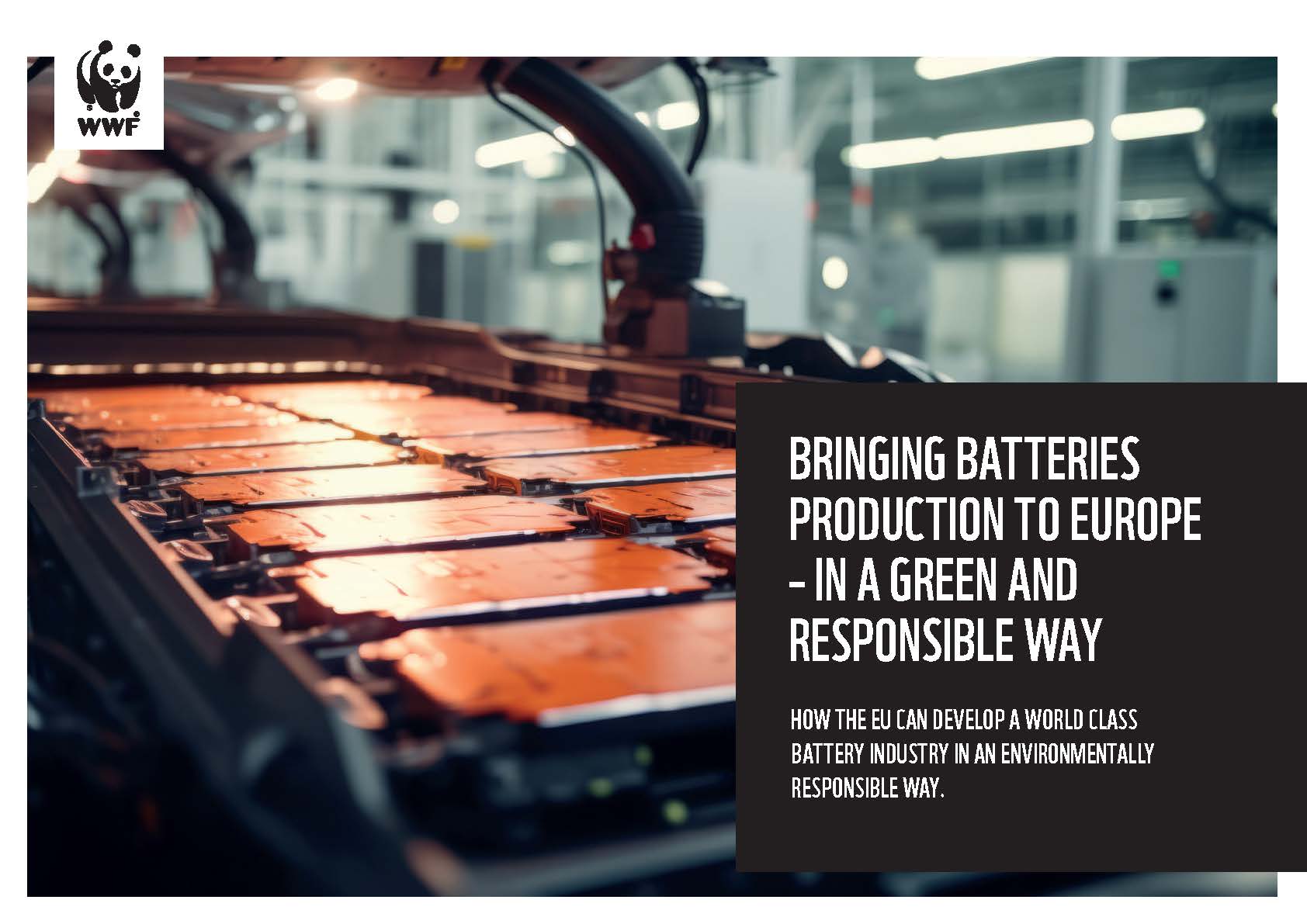

New EU rules call for 40% of Europe’s critical raw materials to be processed within the member states. The aim is to boost net-zero technologies and remain competitive in a decarbonising global economy – while meeting sustainability goals. A new report from WWF, with support from Systemiq, looks at how the EU can develop a world-class and environmentally responsible battery industry.

Demand for electric vehicle (EV) batteries is projected to grow exponentially to 2030, both globally and in the European Union. And producing the batteries relies, in turn, on ‘energy-mobility transition materials’, such as lithium, nickel, cobalt, manganese and graphite.

New legislation, in the form of the Critical Raw Materials Act (CRMA) and the Net-Zero Industry Act (NZIA), seeks to secure supply of critical raw minerals within EU borders and to increase battery manufacturing in Europe.

A new report by WWF, with support from Systemiq, finds that relocating parts of the battery supply chain could give the EU greater control over production – including its social and environmental factors – and set the highest global standards for sustainable battery production.

The move could open up technical levers, under the EU’s control, to reduce the CO2 footprint of battery production. These include using more secondary transition materials and enhanced recycling technologies. Power purchase agreements – direct contracts between companies and renewable electricity suppliers – could ensure that battery manufacturing is powered by more renewable energy.

The new EU Battery Regulation should start to reduce the CO2 footprint of battery production, gradually introducing carbon footprint performance classes, declaration requirements and limits on the carbon footprint of batteries for electric vehicles, light means of transport (eg, e-bikes and scooters) and rechargeable industrial batteries, starting from 2025. The report recommends defining the maximum carbon threshold categories of the performance classes as low as possible to push battery producers and stakeholders in the battery value chain in Europe towards the use of green electricity. It’s vital – says Esther Laabs, WWF’s project manager on raw materials and batteries – that those thresholds aren’t set too high, so that the industry really starts to move in the direction of low-emission batteries.

The report cautions against using a blanket benchmark for reshoring production processes. “The 40% benchmark needs to be specifically evaluated for each raw material, along with the conditions in the respective countries, to work out to what extent it makes sense to bring those processes to Europe”, explains Tilmann Vahle, Systemiq’s Director for Sustainable Mobility and Batteries. The report authors cite the example of processing lithium sulphate – potentially up to 5 times more emissions-intensive in the EU than using current technologies in Chile.

“Overall, bringing the battery value chain to Europe is the right thing to do, says Vahle, even if that means bringing higher energy use and emissions back within our borders. Those negatives are outweighed by a faster and more environmentally friendly transition to electric-powered mobility – not least because of the EU’s higher environmental standards for industry.”

But technologies and relocation are not the whole story: creating the conditions for consumers to use more public transport and use cars more in sharing schemes, rather than each household buying its own private cars, have the greatest savings potential in terms of carbon emissions and resource use.

That’s why the WWF report recommends that technological advances need to go hand in hand with demand reduction for transition materials. Policies must foster innovation by encouraging the design of services and goods that require fewer resources to provide similar services.