Achieving

Circularity

Synthesis Report

A LOW-EMISSIONS CIRCULAR

PLASTIC ECONOMY IN NORWAY

7 CRITICAL INSIGHTS ➜

ON THE PATH TO A CIRCULAR AND NET ZERO ALIGNED NORWEGIAN PLASTIC SYSTEM

Preface

Reasons for writing this report

The world is facing a critical plastic pollution challenge that requires it to deepen its understanding of the root causes of plastic waste and define pathways to eliminate it at a global scale. By 2024, a global treaty is expected to be negotiated by UN member states that enables a thriving circular plastic economy capable of eradicating plastic pollution.

Norway has the ambition to continue to be a frontrunner on addressing this challenge, and – together with Rwanda – is leading the High Ambition Coalition to End Plastic Pollution,

committed to developing a successful global plastic treaty. The goal of this study is to lay out a pathway that can accelerate Norway’s own transition towards a low-emissions, zero-waste circular plastic economy by 2040. This is done through an in-depth analysis of different sectors of the plastic system and identifying tailored roadmaps with strategies that design out waste and pollution, eliminate unnecessary production and consumption, keep products and materials in the economy for longer, safely collect and dispose of waste that cannot be economically processed, and dramatically reduce greenhouse gas emissions.

This report provides a synthesis of the two studies produced in this series: “Achieving Circularity for Single-Use Plastics” and “Achieving Circularity for Durable Plastics”. The former focuses on consumable applications of plastics in Packaging and Household Goods of a single-use nature with lifetimes of less than a year. The latter focuses on durable plastics in five sectors: Construction, Textiles, Electronics & Electricals, Automotive, and Fishing & Aquaculture.

Together, these studies cover ~80% of Norwegian plastic consumption, making it one of the most holistic views of a national plastic system presented to date.

Plastics have been instrumental to the growth of all sectors of Norway’s economy, but today’s system, considering all in-scope sectors, is around 78% linear, meaning 78% of plastic waste is either incinerated, landfilled, or left in nature.

The objective of this Synthesis Report is therefore to paint a picture of the most ambitious levels of circularity and greenhouse gas emissions (GHG) abatement that could be realistically achieved by the Norwegian plastic system by 2040, providing each individual sector with a clear “North Star” to aim for.

The analysis underpinning this report was supported by 16 Norwegian and international experts, and the Norwegian consultancy Mepex.

It builds on the ‘Breaking the Plastic Wave’, and methodology published by Systemiq and The Pew Charitable Trusts in 2020. Norway is the first country to apply this methodology to such a comprehensive scope of plastic sectors.

It builds on the ‘Breaking the Plastic Wave’, and methodology published by Systemiq and The Pew Charitable Trusts in 2020. Norway is the first country to apply this methodology to such a comprehensive scope of plastic sectors.

Our hope and objective is that this report can strengthen collaboration along the value chain, both in Norway and across the region, and guide policymakers, industry leaders, investors, and civil society in preparing the most effective initiatives to achieve a zero-waste circular plastic economy aligned with Norway’s nationally determined emissions reduction targets.

This Synthesis Report and the two studies in the “Achieving Circularity” series set out to achieve the following objectives:

A

To produce a data-driven scenario analysis for the entire Norwegian plastic system to inform strategies and resource allocation for all stakeholders in the value chain.

B

To provide evidence-based recommendations on priority areas needed to transform the Norwegian plastic system.

C

To strengthen partnerships and collaboration between stakeholders across the value chain, in both the public sector and civil society, by providing a quantitative reference point to facilitate evidence-based conversations in order to explore different strategies for achieving a better plastic system in Norway.

Cecilie Lind

CEO

Handelens Miljøfond

Yoni Shiran

Partner

Systemiq

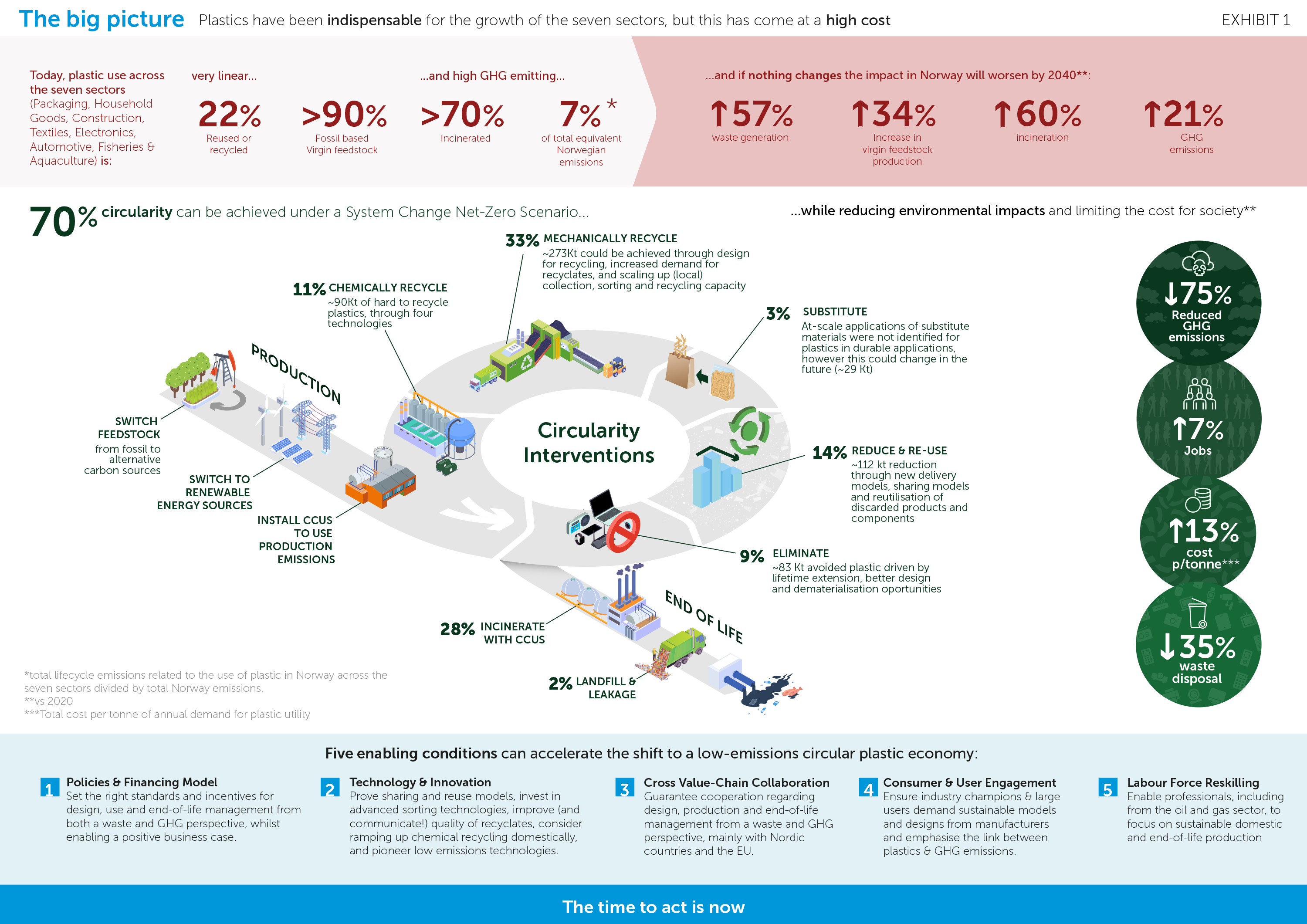

EXHIBIT 1

THE BIG PICTURE

(For Single-Use and Durable Plastics)

Plastics have been indispensable for the growth of the seven sectors, but this has come at a high cost.

Today, the use of plastic across the seven sectors (Packaging, Household Goods, Construction, Textiles, Electronics, Automotive, Fisheries & Aquaculture) is:

very linear…

22

Reused or Recycled

x

90

Fossil based virgin feedstock

…and high GHG emitting

70

is incinerated

x

7

of total equivalent

Norwegian emissions*

…and if nothing changes the impact in Norway will worsen by 2040:

57

Increased waste generation

34

Increased virgin feedstock production

60

Increased incineration

21%

Increased GHG emissions

70% circularity can be achieved under a System Change Net-Zero Scenario…

…while reducing environmental impacts and limiting the cost for society **

*total lifecycle emissions related to the use of plastic in Norway across the seven sectors divided by total Norway emissions.

**vs 2020

***Total cost per tonne of annual demand for plastic utility

Five enabling conditions

can accelerate the shift to a low-emissions circular plastic economy:

1

Policies & Financing Model

Set the right standards and incentives for design, use and end-of-life management from both a waste and GHG perspective, whilst enabling a positive business case.

2

Technology & Innovation

Prove sharing and reuse models, invest in advanced sorting technologies, improve (and communicate!) quality of recyclates, consider ramping up chemical recycling domestically, and pioneer low emissions technologies.

3

Cross Value-Chain Collaboration

Guarantee cooperation regarding design, production and end-of-life management from a waste and GHG perspective, mainly with Nordic countries and the EU.

4

Consumer & User Engagement

Ensure industry champions & large users demand sustainable models and designs from manufacturers and emphasise the link between plastics & GHG emissions.

5

Labour Force Reskilling

Enable professionals, including from the oil and gas sector, to focus on sustainable domestic and end-of-life production

The time to act is now

About

About Handelens Miljøfond

(Norwegian Retailers’ Environment Fund)

Handelens Miljøfond is Norway’s largest private environmental fund, and Norway’s most important measure for complying with the EU Plastic Bags Directive. The fund supports national and international projects that reduce plastic pollution, increase plastic recycling, and reduce the consumption of plastic bags.

The fund’s vision is to promote a circular plastic system and a pollution free environment. In 2021, Handelens Miljøfond launched “Achieving Circularity” together with Systemiq and Mepex. Part 1 of this study focused on post-consumer plastic packaging and non-electrical household products.

About SYSTEMIQ

SYSTEMIQ is a B Corp founded in 2016 to drive the Paris Agreement and the Sustainable Development Goals by transforming markets and business models in five key systems: nature and food, materials and circularity, energy, urban areas, and sustainable finance.

In 2020, SYSTEMIQ and The Pew Charitable Trusts published “Breaking the Plastic Wave: A Comprehensive Assessment of Pathways Towards Stopping Ocean Plastic Pollution,” an evidence-based roadmap that shows how industry and governments can radically reduce ocean plastic pollution by 2040, upon which this report is based. The findings of our analysis were published in the peer-reviewed journal, Science.

About Mepex

Mepex is a Norwegian independent consultancy firm specializing in waste management, recycling and circular value chains. The aim is to be a catalyst for change, contributing to making the circular economy a reality through resource-efficient and climate-friendly solutions.

Mepex combines analytical competence with extensive experience in design, construction, and operation of waste management infrastructure to support authorities, municipalities, organisations, and businesses in formulating strategies and achieving their environmental goals

Endorsements

Acknowledgements

Expert Panel

This work was developed together with a panel of 16 Norwegian experts with diverse backgrounds and perspectives. We would like to thank them for their insights, contributions and support.

Anja Ronesen

Marketing & Communications Manager

RENAS

Åsa Stenmarck

Material Flow Expert

Swedish Environmental Protection Agency

Christian Karl

Research Scientist

SINTEF Industry

Elisabete Fernandes Reia da Costa

Research Scientist

SINTEF Industry

Elisabeth Magnus

Former Senior Environmental advisor

Nordic Ecolabelling

Hanne Digre

Chief Sustainability Officer / PhD

ScaleAQ

Helene Øyangen Lindberg

Research Scientist

SINTEF Manufacturing

Kay Riksfjord

Downstream Manager

Revac

Board Member

BIR Plastic Committee

Kjersti Busch

Co-founder

Salt

Lars Fallmyr

Operations Manager

Bilgjenvinning AS

Linda Refvik

CEO

NF&TA

Thor Kamfjord

Director of Sustainability and Social Responsibility

Norner

STUDY 1 ONLY

Cecilie Lind

CEO

Handelens Miljøfond

Christoffer Vestli

International Relations Officer

European Commission

Johannes Daae

Head of Development

Grønt Punkt Norge

Marius Gjerset

Technology Manager

ZERO

Project core team

Systemiq

Yoni Shiran, Lead Partner

Ben Dixon, Partner

Peter Goult, Project Director

Marloes van der Meer, Project Manager

Alexandre Kremer, Project Manager, Study 1

Andrea Bath, Associate

Hannah Maral, Associate

Jamie Harrison Grundy, Associate

Trishla Shah, Associate

Xavier Laguarta, Associate

Andreas Wagner, GHG Expert

Ulrike Stein, Communications Lead

Handelens Miljøfond

Lars Brede Johansen, COO

Sjur Kvifte Nesheim, Analyst

Hanne M. Hjelmungen Lorvik, Communications Advisor

Mepex

Frode Syversen, Mepex Managing Director

Miriam Mekki, Project Manager

Carl Frederik Mørch-Kontny, Analyst

Simen Randby, Analyst

Espen Mikkelborg, Analyst

Sølvi Rønnekleiv Haugedal, Analyst

Kristiane Rabben, Analyst

Contributors

We would also like thank the following people who have generously contributed their time and expertise to the report:

Anne Slaaen: CEO and Creative Director Team Kameleon AS

Evelyn Luna Victoria: Oceans Senior Manager, WWF

Justin Greenaway: Commercial Manager, Sweeep Kuusakoski Ltd

Mike Muskett: Independent Consultant

Nadia Balducci: Clean Oceans Specialist, WWF

Paritosh Deshpande: Associate Professor, Norwegian University of Science and Technology (NTNU)

Pascal Leroy: Director General of the WEEE Forum

REV Ocean

Sarah Downes: External Affairs Manager, REPIC

Tim Huntington: General Manager Poseidon Aquatic Resource Management Ltd

Introduction

Plastic has been a key enabler of economic growth across many sectors in Norway.

Its affordability, low density, and durability paved the way for plastic to become the material of choice in a wide range of applications, from food packaging to industrial cables to fishing nets. It is this diversity of application that has led to the ubiquity of plastics.

However, the rise in plastic consumption has come at a high cost to both the environment and society and is now incompatible with Norway’s ambitions to achieve circularity and meet key climate targets. Today there is an urgent need for Norway to steer its plastic system off the unsustainable trajectory it is currently on, and towards a highly circular, low-emissions, resource efficient pathway.

This Synthesis Report provides seven key insights on the transformation of the Norwegian plastic system.

It is a summary of the two studies in this series: “Achieving Circularity for Single-Use Plastics” and “Achieving Circularity for Durable Plastics”. The former focuses on consumable applications of plastics, herein referred to as ‘Consumables’, while the latter focuses on durable plastic applications. Together, the seven sectors analysed in these two studies cover ~80% (~710,000 tonnes) of Norway’s plastic consumption (Exhibit 2) and around two thirds (~500,000 tonnes) of its waste generation, providing the most comprehensive view of the Norwegian plastic system available to date.b

b All references to plastic in this report refer to plastic applications within these seven sectors alone, unless otherwise specified. Estimated waste numbers are higher than in previously reported studies due to a combination of increased consumption, and a deeper assessment of both the five durable sectors in scope of Part 2 and the “other” categories.

EXHIBIT 2

The seven sectors analysed in this study account for 80% of total plastic demand in Norway in 2021

Composition of the Norwegian plastics market by sector (kt)

Source: Mepex analysis

The fact that Norway imports most of its plastic and plastic products, and exports over a third of its plastic waste, has implications for how to assess both the impacts of the current plastic system and any prospective strategies, and was therefore considered across the key findings. Even though collaboration with other Nordic states and the EU will be key to defining future plastic solutions, this also poses a key question in terms of the extent to which Norway can domesticate its plastic value chain versus focusing on driving change abroad.

The analyses synthesised in this report rely on a stock-and-flow model, based on the approach used in the 2020 “Breaking the Plastic Wave” report, adjusted to the Norwegian context and extended to include all the sectors shown in Exhibit 2.

The model quantifies stocks and flows, and the relationship between them, under three different scenarios:

- a Baseline Scenario, in which current trends are projected out;

- a System Change Scenario, in which circularity interventions are ambitiously applied across all sectors and over the full value chain; and

- a Net-Zero Scenario, in which greenhouse gas (GHG) emissions abatement measures are modelled on top of the System Change Scenario.

As well as the volumetric analysis, additional layers have been modelled to estimate the economic, climate and employment implications of different interventions and scenarios.c

cThe numbers included in this study are modelled outputs, accurately represented from our model, which could be perceived as false precision. It is important to emphasise that these are scenario outputs, not forecasts, and therefore there is a margin of error. Additional information about the analysis and underlying assumptions can be found in the technical reports accompanying each study in the series.